GUIDE TO FORMING THE WIDEBODY SHQRP HQ’S PANELS Street Machine

We are able to produce high quality sheet metal forming dies for car body parts from steel and aluminum materials, as well as from high and extra high strength materials. We master metal forming in all its facets - from component development and simultaneous engineering to the production of die sets for mass production. Needed forming dies.

Basics for Classic Car Body Filler Work Classic Auto Advisors

For automotive metal forming, the blank is often made of sheet metal, which can be stamped, cut or bent into a shape needed for an automobile's body. Alternatively, it can be a solid block of metal in a cubical or lens-like shape. Here are some ways that a metal workpiece can be deformed during the automotive manufacturing process:

Visit MACHINE Shop Café (Austin Custom Car Metal Shaping) Promoted by The Fab Forums Metal

Megacasting: a chance to rethink body manufacturing. The aluminium die-casting process could revolutionise body construction. Professor Wolfram Volk, the department head for forming technology and casting at the Technical University of Munich, explains the advantages and disadvantages of so-called 'mega'- or 'gigacasting'. Several.

Four Column Hydraulic Car Body Panels Forming Making Machine Hydraulic Press China Car Body

When you visit a website, it may store or collect information on your browser, primarily in the form of cookies. This information can be about you, your preferences or your device and is used primarily to make the website work as you expect. The information usually doesn't directly identify you, but it can provide a more personalized web.

OEM Custom Vacuum Forming ABS Plastic Car Body Shell DitaiPlastic

The Automotive Body Manufacturing Systems and Processes The Automotive Body Manufacturing Systems and Processes A comprehensive and dedicated guide to automotive production lines, The Automotive Body Manufacturing Systems and Processes addresses automotive body processes from the stamping operations through to the final assembly activities. To begin, it discusses current metal forming.

Innovative Car Body Curing from the InsideOut 20181105 PCI Magazine

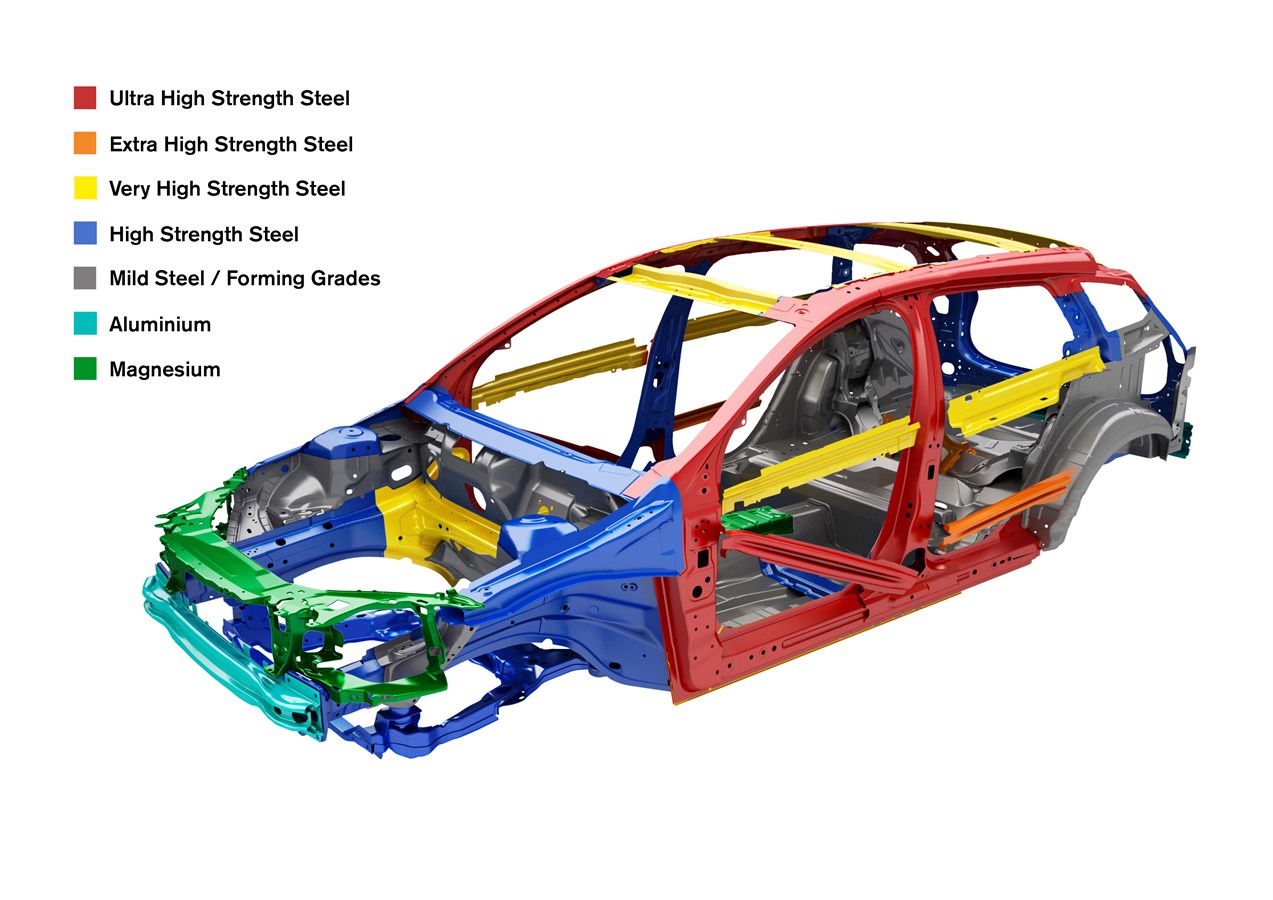

The need for lighter, stronger, more rigid vehicle structures will increasingly require complex hydroformed structural tubes to increase strength, and decrease weight, cost and part count. This effort will increase the use of high strength, low alloy (HSLA) steel, in place of SAE 1006/1008 or 1010 steel. Traditional hydroforming techniques.

Vacuum Forming RC Car Body / FLOW A3desk YouTube

Hot stamping is an established forming process used in the automobile industry to meet the demands for safety and lightweight design combined with an appropriate setting of mechanical properties [ 4 ]. Almost 30% of modern car body parts are processed by hot stamping, and the amount is continuously rising [ 5 ].

Radio Controlled Car Body Vacuum Forming with Cement Mold rc YouTube

Sheet metal forming is one of the most important key technologies in manufacturing industry. It may be reasoned by several facts, among them the economy of the sheet-forming processes concerning the. Expand

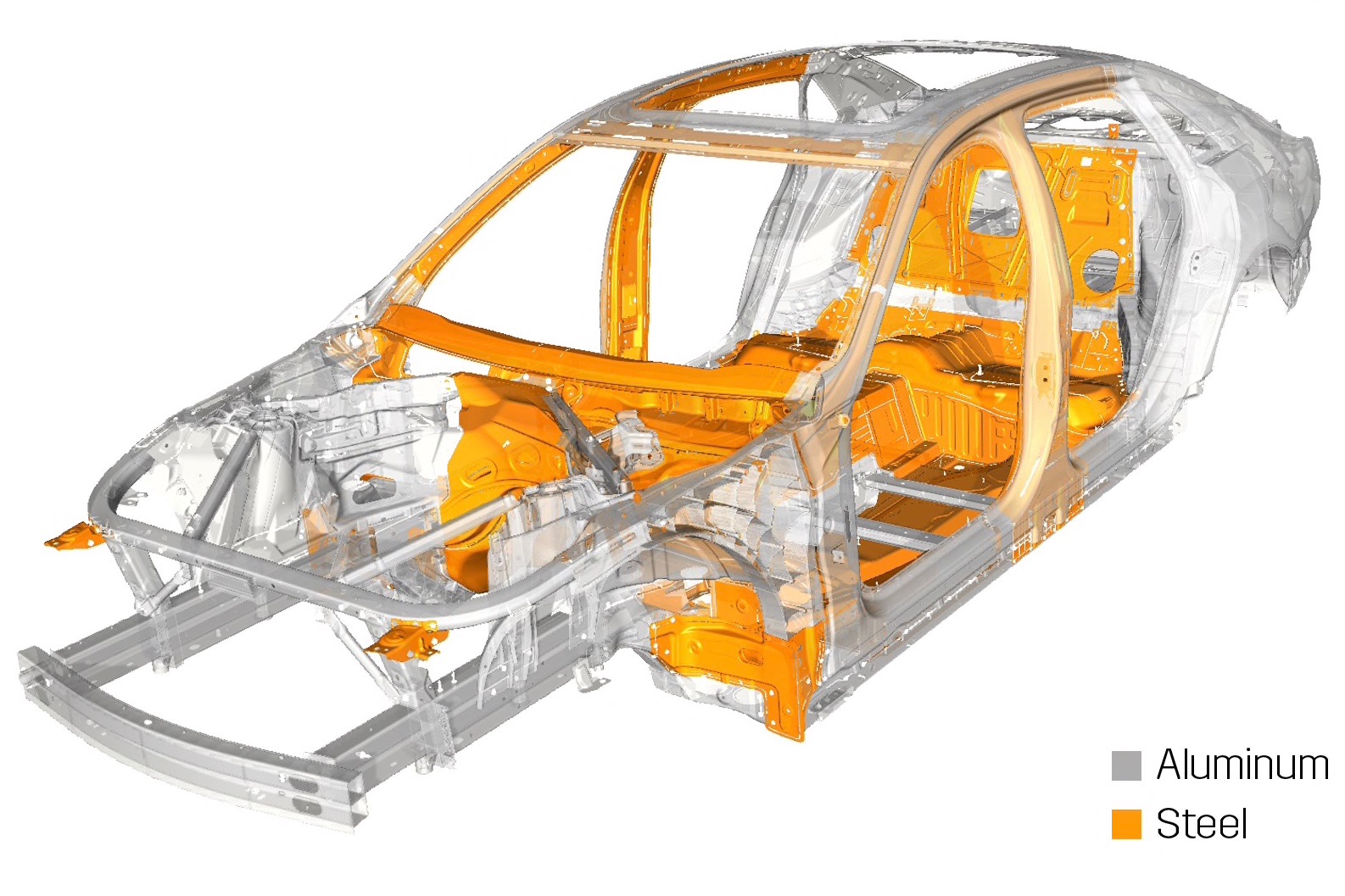

The body Intelligent mix of materials for maximum strength Porsche Newsroom

An instrumental technique that has revolutionized the production of automotive components, particularly body panels, is sheet metal fabrication. This complex process leverages technology and human expertise to transform simple sheet metal into the sleek, aesthetic, and functional body panels that give each vehicle its unique identity.

AP&T’s experts “Our solution for hot forming of car body parts in highstrength aluminum can

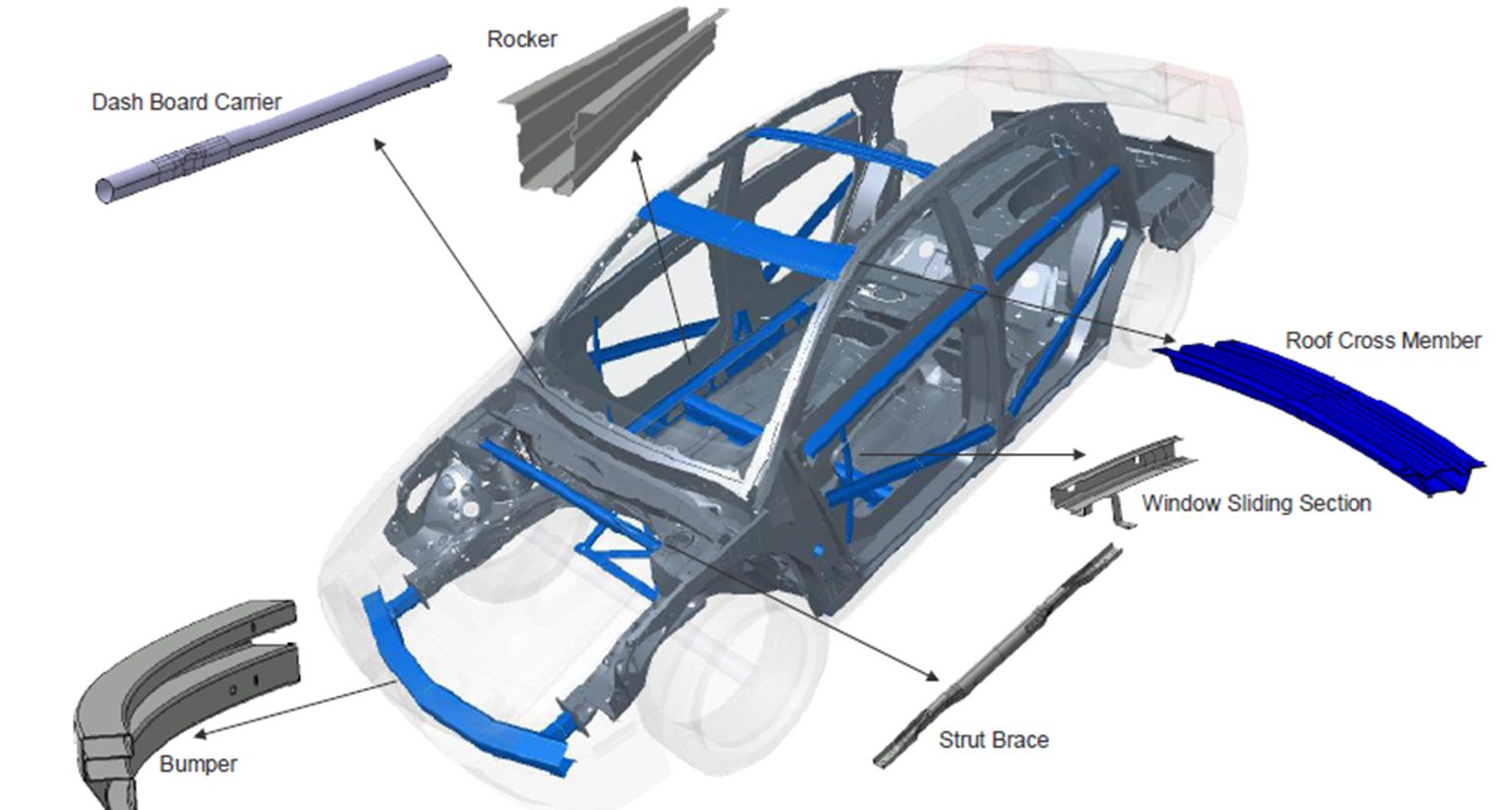

Module 2 - Panel Forming, Profiling, onSeptember 27/28, continues the tradition of Automotive Circles Forming in Car Body Engineering conference and addresses progress in the panel-forming press plant and tool shop, as well as in other secondary forming technologies, such as profile forming, roll or blow forming:

Roll Forming AHSS Guidelines

Stamping Auto body panels •3 to 5 dies each • Prototype dies ~ $50,000 • Production dies ~ $0.75-1. •Super-plastic forming - cheap tooling, net thinning, expensive sheet metal, slow, very high formability. Stamping alum car hoods • Final part = 5.4kgs • Total number of parts made = 400

HandForming Car Bodies With an English Wheel

Al and Dan talk about how to hammer form sheets of metal into cars, what tools are needed and how to use those tools. Big thanks to Covell for sending us som.

MC MKI 3D Engineers Car Creation Solutions bespoke car design Bespoke cars, Metal shaping

Automotive Bodywork: How to Form, Fit and Smooth Sheetmetal March 21, 2015 by Muscle Car DiY This article covers shaping, fitting, and smoothing sheetmetal with hand tools and power forming equipment. These are the operations that turn flat stock into the finished shapes that you need and want.

Unibody vs. Body on Frame What's the Difference? CARFAX Blog

When it comes to metal shaping and forming for automotive purposes, there are a few general categories of work: sheet metal (large and small pieces), pipe or tube bending, and metal shrinking and stretching.

Perodua Bezza Av Smartfren U

Sheet Metal Forming Techniques. Bending and stamping are cold-forming processes widely used in the automotive part manufacturing industry. 5. Bending .. automotive body panel Car Bodies and Frames. The structural integrity of an automobile depends on its body and frame, and a proper manufacturing process should be employed..

Enhancing Durability of Automotive Stamping Dies with Plasma Nitriding

Car Body Press Technology Solving the dilemma of light weight versus safety. Achieving both light body weight and safety is a tough problem to solve. Simply making the steel plate thinner to save weight diminishes its collision strength. Unipres employs HTSS forming technology along with product design technology to solve this dilemma.